RoyOxy RAR 921

RoyOxy RAR 921 is the tetra-glycidyl derivative of methylene dianiline, also known as TGDDM (tetra-glycidyl diaminodiphenyl methane) having the following structure:

RoyOxy RAR 921 epoxy resin in combination with RoyOxy RAC 9910 epoxy curing agent is used to formulate prepregs mainly used in the aerospace industry. The cured prepreg has a Tg of 2400C.

RoyOxy RAR 921 can also be used with anhydride hardeners like Nadic methyl anhydride (NMA), hexahydrophthalic anhydride (HHPA) and methyl tetrahydrophthalic anhydride (MTHPA) or with an aromatic amine hardener, diethyl toluene diamine (DETDA) for filament winding. A Tg up to 2350C is obtainable with the latter system.

RoyOxy RAR 922

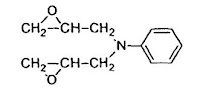

RoyOxy RAR 922 epoxy resin is the tetra-glycidyl derivative of o,o’-diethyl methylene dianiline represented by the formula:

Although this resin does not give quite as high a glass transition temperature as RoyOxy RAR 921, its lower viscosity of 9000-11000 cp at 250C is an advantage, especially in potting and encapsulating compounds. It is recommended with anhydride epoxy curing agents as well as with RoyOxy RAC 9915 epoxy curing agent in formulating casting resin systems for submersible and tooling applications and for high radiation resistant components.

RoyOxy RAD 104

RoyOxy RAD 104 is diglycidyl aniline.

RoyOxy RAD 104 has a low viscosity of 100-200 cP and is used as a reactive diluent particularly in those applications where a minimal sacrifice of heat deflection temperature is called for. A blend of RoyOxy RAR 921 and RoyOxy RAD 104 epoxy diluent in the ratio 75:25, cured with RoyOxy RAC 9923 epoxy curing agent (aromatic-aliphatic amine blend) gives a Tg as high as 1960C.

RoyOxy BMI11

RoyOxy BMI 11 is a bismaleimide resin usually cured with o,o’-diallyl bisphenol-A. The resin and curing agent have the structures below:

4,4-Bismaleimidodiphenylmethane o’o-Diallyl Bisphenol A

The properties of this bismaleimide system are:

- Outstanding heat resistance with a Tg as high as 3100C

- Good toughness

- Very high resistance to water

- Processability by hot melt

For more detail or information about Epoxy resin systems, Visit http://www.royceintl.com/blog/